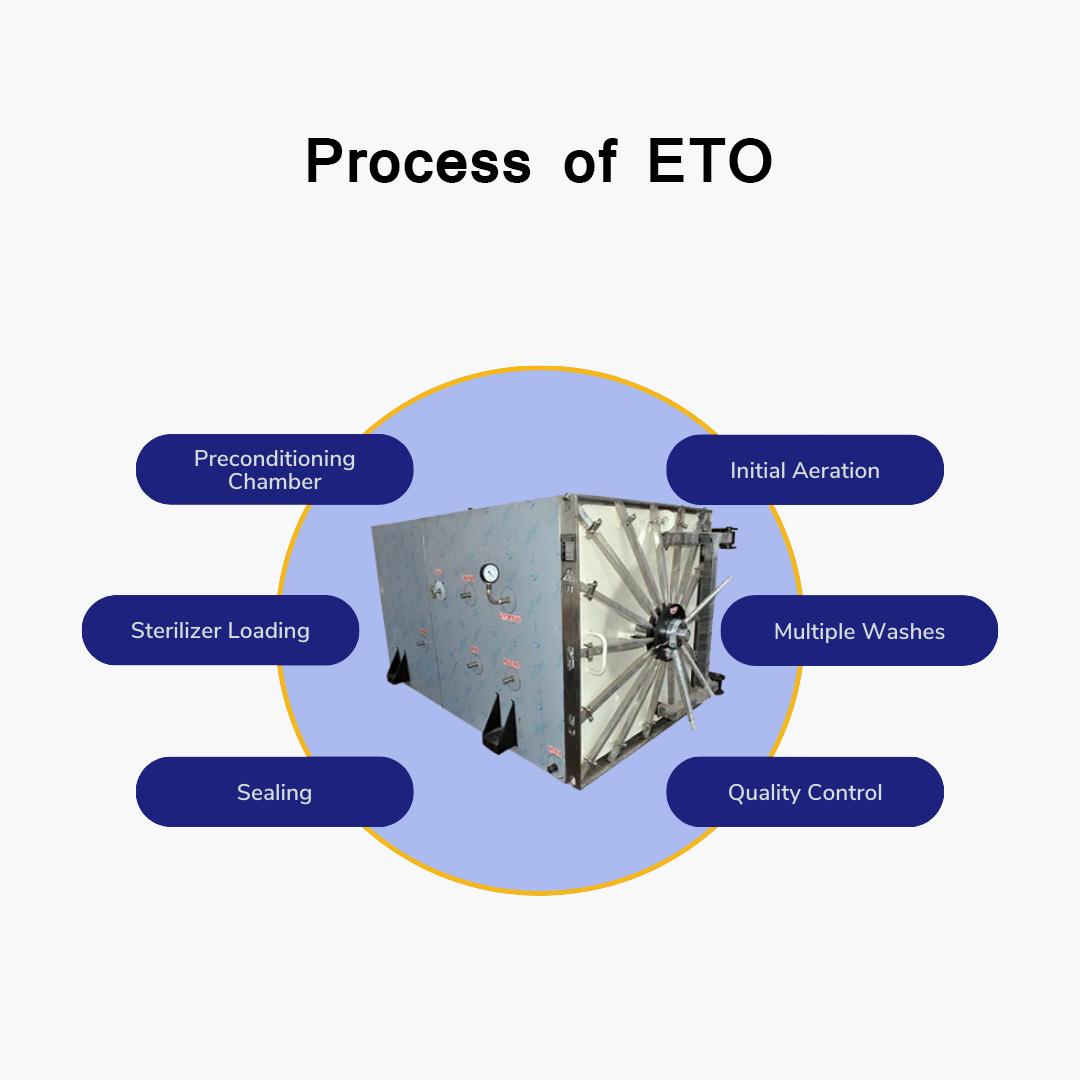

Process Operation of ETO Sterilizer

The process operation of an ETO (Ethylene Oxide) Sterilizer involves several stages to ensure effective sterilization. Here is a step-by-step outline of the typical ETO sterilization process:

Preconditioning Chamber:The loaded items are placed in a preconditioning chamber where temperature and humidity are controlled to prepare them for sterilization.

Sterilizer Loading: The preconditioned items are transferred to the sterilizer chamber.

Sealing: The sterilizer chamber is sealed to ensure a controlled environment.

Initial Vacuum: A vacuum is drawn to remove air and reduce the pressure inside the chamber, which helps in effective gas penetration.

Initial Aeration: After the exposure period, the gas is evacuated from the chamber.

Multiple Washes: The chamber may be flushed with air or an inert gas multiple times to remove residual ethylene oxide.

Extended Aeration: The items may remain in the aeration chamber for several hours to several days, depending on the material and regulatory requirements.

Quality Control: The sterilized items undergo quality control checks to ensure that the sterilization process was effective.