Key Features and Benefits of Horizontal ETO Sterilizers:

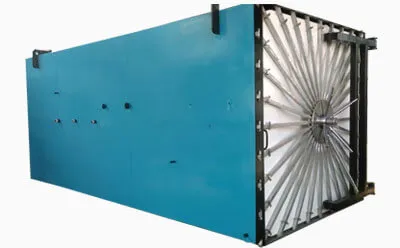

Horizontal Chamber Design:

Horizontal ETO Sterilisers have a sterilisation chamber that is horizontally positioned. This design ensures uniform and thorough sterilisation of the goods being processed by distributing ETO gas evenly throughout the chamber. It's especially useful for things that are sensitive to vertical orientation or require consistent gas exposure.

Efficient Gas Penetration:

The horizontal orientation of the chamber facilitates efficient gas penetration into the items being sterilized. ETO gas can reach all areas of the load more effectively, including hard-to-reach spaces and complex geometries. This enhances the sterilization efficacy and ensures high-level microbial kill rates.

Loading and Unloading Ease:

The loading and unloading operation is made easier with a horizontal arrangement. Items can be placed on trays or racks and slid into the sterilisation chamber without the necessity for vertical stacking. This streamlines the process and saves time, especially when dealing with larger or heavier products.

Advanced Control Systems:

Horizontal ETO Sterilisers include modern control systems that allow for exact monitoring and control of important parameters. Temperature, humidity, pressure, and exposure time can all be precisely controlled to provide optimal sterilisation conditions for various products.

Safety Features:

Safety is a top priority in Horizontal ETO Sterilizers. They are designed with comprehensive safety features to protect operators and ensure a secure working environment. These features may include gas monitoring systems, emergency shut-off mechanisms, pressure relief valves, and explosion-proof designs, ensuring the utmost safety during the sterilization process.