By admin / 27 Jan 2024

Ethylene oxide sterilization consists of five stages: preconditioning and humidification, gas introduction, exposure, evacuation, and air washes. In the field of healthcare, sterilization of medical tools is critical to preventing infections and ensuring patient safety. This in-depth examination goes into the various phases of the hospital sterilization process, shining light on the painstaking methods and policies that healthcare institutions employ to maintain the greatest levels of hygiene.

Discover the careful procedures for gathering, cleaning, inspecting, and packaging medical devices. Learn about several sterilization techniques, such as autoclaving, ethylene oxide sterilization, gamma radiation, and dry heat sterilization. Learn how thorough monitoring, documentation, and quality assurance are essential for ensuring the sterilization process's effectiveness. Learn about the critical role sterilization plays in ensuring patient safety and reducing the spread of pathogens within healthcare institutions.

The Hospital Sterilization Process: Safeguarding Healthcare Hygiene

1. Collection and Sorting:

Used medical instruments from various hospital departments undergo systematic collection and sorting. This initial step sets the stage for the subsequent processes, ensuring that all instruments are accounted for.

2. Pre-cleaning:

Prior to sterilization, equipment are pre-cleaned to eliminate organic and inorganic contaminants. This crucial phase removes blood, tissue, and other debris, preparing the tools for sterilization.

3. Inspection and Sorting:

Each instrument is thoroughly inspected to determine its condition and eligibility for sterilization. Sorting occurs based on the type of instrument and the sterilization process used.

4. Packaging:

Proper packaging is a pivotal step in maintaining the sterility of instruments. Sterile packaging materials are employed to ensure that instruments remain uncontaminated until they are ready for use.

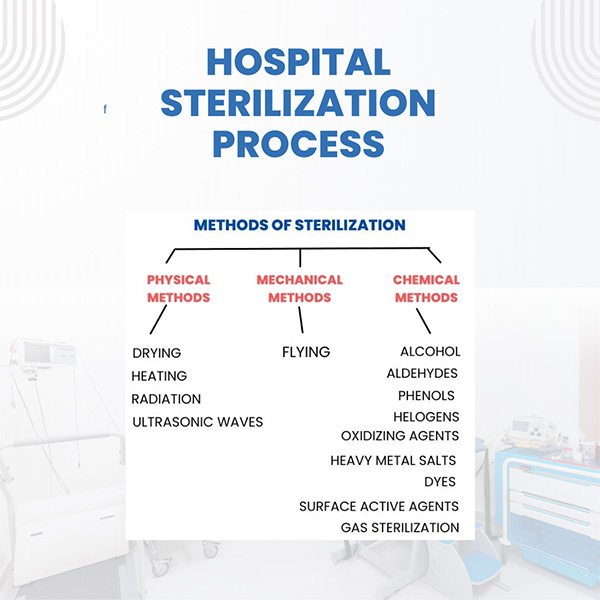

5. Sterilization Methods:

Hospitals employ various sterilization methods based on the nature of the instruments:

Autoclaving: Utilizing steam under pressure to achieve high temperatures and eliminate microorganisms.

Ethylene Oxide (ETO) Sterilization: Ideal for heat-sensitive instruments, utilizing a gas to achieve sterilization.

Gamma Radiation: Employed for the sterilization of disposable medical supplies.

Dry Heat Sterilization: Exposing instruments to high temperatures in a dry environment.

6. Sterilization Monitoring:

Regular monitoring is essential for ensuring that the sterilizing process works properly. Biological and chemical markers are used to ensure that the sterilization requirements are met.

7. Storage:

Sterilized instruments are carefully stored in specified areas, under correct conditions to avoid contamination and to ensure their readiness for use when needed.

8. Transportation:

Sterilized instruments are transported to different hospital departments with adherence to strict handling procedures. This step is crucial to prevent any compromise to the sterility of the instruments.